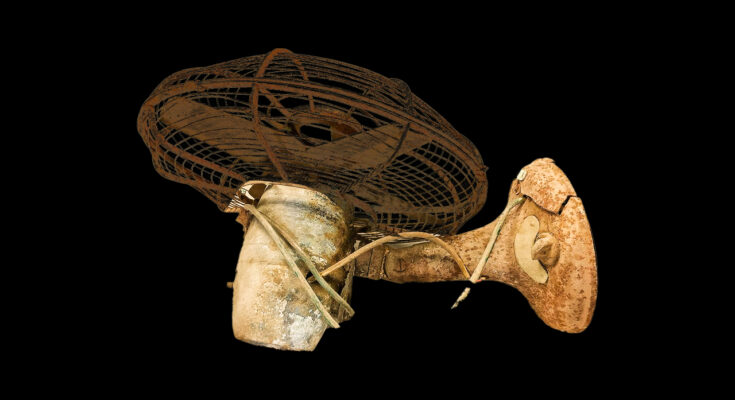

Step-by-Step Guide for Restoring an Old Rusty Electric Table Fan:

1. Safety Precautions:

- Safety Gear: Wear gloves, goggles, and a mask to protect against rust, dust, and chemicals.

- Turn Off Power: Ensure the fan is unplugged, and all power is disconnected before starting.

2. Disassembly:

- Remove Fan Blades and Guard: Use a screwdriver to remove the fan guard and blades. Be careful with the screws and save them for reassembly.

- Remove Motor Housing: Take off the motor housing to expose the motor inside. Take pictures of how the wires are connected, as this will help with reassembly.

- Inspect Parts: Check for worn-out parts like the motor, wires, or capacitor. Identify if any parts need replacing.

3. Cleaning the Rusty Parts:

- Apply Penetrating Oil: Spray the rusty areas with WD-40 or another rust remover and let it sit for 15-30 minutes.

- Use a Wire Brush: Scrub the metal surfaces with a wire brush to remove loose rust and dirt.

- Sandpaper: Use fine-grit sandpaper (400-600 grit) to remove any remaining rust and smooth the surface. This is especially important for the fan blades and body.

4. Clean the Motor:

- Blow Out Dust: Use compressed air or a soft brush to remove dust and debris from the motor. Make sure not to damage delicate internal components.

- Check and Lubricate: Inspect the motor and apply a few drops of machine oil (3-IN-ONE Oil) to the bearings and moving parts to ensure smooth operation.

- Check Wiring: Examine the wiring for any signs of damage. Replace old or frayed wires to prevent electrical hazards.

5. Painting and Polishing:

- Primer and Paint (Optional): If the fan’s body is heavily rusted or scratched, apply a rust-inhibiting primer first. After it dries, paint the fan body with a metal spray paint in your preferred color (Rust-Oleum works well).

- Polish the Blades: If the fan blades are metal, use metal polish (such as Brasso or Flitz) to restore their shine. Polish them carefully using a soft cloth.

6. Replace or Clean Electrical Components:

- Inspect Capacitor: Replace the capacitor if the fan motor struggles to start. Vintage capacitors often degrade over time.

- Replace Power Cord: If the power cord is frayed or worn out, replace it with a new cord for safety. Match the voltage and wattage specifications of the old cord.

7. Reassemble the Fan:

- Reassemble the Motor and Housing: Once the motor is cleaned and lubricated, put the housing back together. Reconnect the wires according to your reference photos.

- Reattach the Blades and Guard: Attach the blades back onto the motor spindle, then screw the guard back into place.

8. Final Test:

- Test the Fan: Plug in the fan and test its operation. Ensure the motor runs smoothly and the fan rotates without wobbling.

- Adjustments: If needed, adjust the motor alignment or re-oil any parts to ensure smooth movement.

9. Optional Finish – Apply Wax:

- Protective Finish: If you want to give the metal parts a final protective layer, apply a coat of wax or a clear protective lacquer to prevent future rusting.

Tools and Materials for Purchase (US Suppliers):

- Penetrating Oil: WD-40 or PB Blaster (available at Home Depot, Lowe’s)

- Metal Polish: Brasso or Flitz Metal Polish

- Rust-Inhibiting Primer: Rust-Oleum Rusty Metal Primer

- Machine Oil: 3-IN-ONE Oil

- Spray Paint: Rust-Oleum Spray Paint

- Replacement Capacitor and Wires: Available at local hardware stores or online at Amazon and Grainger.